MESIN MULDING BLOW TVA 1000L- 10000L

SPESIFIKASI TEKNIS

| Model | TVA-1000L-I | TVA-1000L-II | TVA-1000L-III | TVA-1000L-IV | TVA-1000L-V | TVA-1000L-VI |

| Kapasitas (L) | 200-1000 | |||||

| Jarak clamping (mm) | 1800 | |||||

| Bukaan stroke (mm) | 850-2650 | |||||

| Clamping platen ukuran (WXH) | 1500-1600 | |||||

| Gaya penjepit (KN) | 1000 | |||||

| Ukuran cetakan maksimal | 1200*1500 | |||||

| Motor ekstrusi (kw) | no | 55+55 | 45+55+45 | 37+45+45+37 | 37*5 | 37*6 |

| Diameter sekrup | 120 | 100+100 | 90+100+90 | 80+90+90+80 | 80*5 | 80*6 |

| Sekrup L/D rasio | 30: 1 | |||||

| Daya panas extruder (kw) | 40 | 53 | 70 | 90 | 105 | 120 |

| Kapasitas plasticizing | 300 | 350 | 380 | 400 | 400 | 430 |

| Daya panas (kw) | 40 | 55 | 65 | 65 | 75 | 75 |

| Volume panyimpenan (L) | 40 | |||||

| Daya motor pompa oli (kw) | 37+4.4 | |||||

| Total daya (kw) | 246 | 275 | 350 | 380 | 410 | 450 |

| Ukuran (L * W * H) M | 8. 3*3.6*6.0 | 8. 5*4.5*6.5 | 8. 5*4.5*6.5 | 9*8.5*6.5 | 9*9.5*6.5 | 9*9.5*6.5 |

| Bobot Total (T) | 30 | 32 | 35 | 40 | 45 | 47 |

| Model | TVA-2000L-I | TVA-2000L-II | TVA-2000L-III | TVA-2000L-IV | TVA-2000L-V | TVA-2000L-VI |

| Kapasitas (L) | 500-2000 | |||||

| Jarak clamping (mm) | 2000 | |||||

| Bukaan stroke (mm) | 1300-3300 | |||||

| Clamping platen ukuran (WXH) | 1900*2100 | |||||

| Gaya penjepit (KN) | 1500 | |||||

| Ukuran cetakan maksimal | 1600*1900 | |||||

| Motor ekstrusi (kw) | 130 | 90+90 | 55+75+55 | 100*4 | 37*5 | 37*6 |

| Diameter sekrup | 130 | 120+120 | 100+110+100 | 55*4 | 90*5 | 90*6 |

| Sekrup L/D rasio | 30:1 | |||||

| Daya panas extruder (kw) | 38 | 52 | 75 | 90 | 100 | 105 |

| Kapasitas plasticizing | 400 | 460 | 460 | 460 | 460 | 460 |

| Daya panas (kw) | 70 | 75 | 80 | 80 | 80 | |

| Volume panyimpenan (L) | 70 | |||||

| Daya motor pompa oli (kw) | 40+7.5 | |||||

| Total daya (kw) | 270 | 360 | 390 | 440 | 460 | 510 |

| Ukuran (L * W * H) M | 10*4.5*7.5 | 10*4.5*7.5 | 10*5.0*7.5 | 10*9*7.5 | 10*9.5*7.5 | 10*11*7.5 |

| Bobot Total (T) | 38 | 39 | 42 | 50 | 55 | 60 |

| Model | TVA-3000-I | TVA-3000-II | TVA-3000-III | TVA-3000-IV | TVA-3000-V |

| Kapasitas (L) | 1000-3000 | ||||

| Jarak clamping (mm) | 2100 | ||||

| Bukaan stroke (mm) | 1300-3400 | ||||

| Clamping platen ukuran (WXH) | 2100*2200 | ||||

| Gaya penjepit (KN) | 2000 | ||||

| Ukuran cetakan maksimal | 1800*2100 | ||||

| Motor ekstrusi (kw) | 160 | 110+110 | 90+110+90 | 75+90+90+75 | 75*5 |

| Diameter sekrup | 150 | 120+120 | 110+120+110 | 100+110+110+100 | 100*5 |

| Sekrup L/D rasio | 30:1 | ||||

| Daya panas extruder (kw) | 40 | 65 | 90 | 120 | 135 |

| Kapasitas plasticizing | 450 | 500 | 550 | 600 | 600 |

| Daya panas (kw) | 80 | 80 | 95 | 110 | 110 |

| Volume panyimpenan (L) | 120 | ||||

| Daya motor pompa oli (kw) | 42+7.5 | ||||

| Total daya (kw) | 320 | 420 | 520 | 580 | 610 |

| Ukuran (L * W * H) M | 12*5.2*8.5 | 12*6.0*8.5 | 12*6.0*8.5 | 12*12.5*8.5 | 12*12.5*8.5 |

| Bobot Total (T) | 48 | 55 | 63 | 70 | 75 |

| Model | TVA-5000-II | TVA-5000-III |

| Kapasitas (L) | 2000-5000 | |

| Jarak clamping (mm) | 2400 | |

| Bukaan stroke (mm) | 1600-4000 | |

| Clamping platen ukuran (WXH) | 2400*2600 | |

| Gaya penjepit (KN) | 3200 | |

| Ukuran cetakan maksimal | 2200*2400 | |

| Motor ekstrusi (kw) | 132+132 | 110+132+110 |

| Diameter sekrup | 130+130 | 110+130+110 |

| Sekrup L/D rasio | 30: | 1 |

| Daya panas extruder (kw) | 100 | 110 |

| Kapasitas plasticizing | 700 | 700 |

| Daya panas (kw) | 120 | 130 |

| Volume panyimpenan (L) | 18C | |

| Daya motor pompa oli (kw) | 75+11 | |

| Total daya (kw) | 550 | 630 |

| Ukuran (L * W * H) M | 14*11*8.5 | 14*11*8.5 |

| Bobot Total (T) | 58 | 80 |

| Model | TVA-10000-II | TVA-10000-III |

| Kapasitas (L) | 5000-10000 | |

| Jarak clamping (mm) | 2800 | |

| Bukaan stroke (mm) | 1700-4500 | |

| Clamping platen ukuran (WXH) | 3000*3600 | |

| Gaya penjepit (KN) | 5500 | |

| Ukuran cetakan maksimal | 2800*3400 | |

| Motor ekstrusi (kw) | 160+160 | 132*3 |

| Diameter sekrup | 150+150 | 130*3 |

| Sekrup L/D rasio | 35:1 | |

| Daya panas extruder (kw) | 110 | 130 |

| Kapasitas plasticizing | 900 | 950 |

| Daya panas (kw) | 150 | 165 |

| Volume panyimpenan (L) | 340 | |

| Daya motor pompa oli (kw) | 80+11 | |

| Total daya (kw) | 720 | 800 |

| Ukuran (L * W * H) M | 16*13*10 | 16*13*10 |

| Bobot Total (T) | 170 | 220 |

1. "A" Series uga Applied kanggo gawé macem-macem produk jotosan nyetak, kayata drum kimia, toolbox dicekel bocah dolanan dolanan, kursi, auto parts lan pallet.Machine effortlessly bisa nyimpen materi ing wektu cendhak karo desain accumulator mati sirah, lan karo sistem kontrol hydraulic diimpor, mlaku luwih andal lan ajeg.Kita uga nganggo sistem pengontrol parison sing luwih maju kanggo malah kekandelan tembok produk.

2. Jumlah lapisan: 1 lapisan nganti 3 lapisan.

3.Clamping Struktur: Telung piring lan kepekso lengen pindho narik-rod bisa bebarengan karo clamping structure.Plates cukup amba kanggo terus jamur ukuran gedhe lan jamur opening & nutup makaryakke stably.Luwih penting deformasi ora katon.

Deskripsi Produk

Biasane kita terus-terusan nyedhiyakake dhukungan para pembeli sing paling teliti, uga macem-macem desain lan gaya kanthi bahan sing paling apik.Usaha kasebut kalebu kasedhiyan desain sing disesuaikan kanthi kacepetan lan kiriman kanggo Pilihan Massive kanggo HDPE Botol Plastik Extrusion Blow Molding Machine Made in China, Amarga kualitas sing unggul lan rega sade sing kompetitif, kita bakal dadi pimpinan pasar saiki, mesthine. kanggo ora ngenteni kanggo hubungi kita liwat telpon seluler utawa email, yen sampeyan kepincut ing samubarang produk kita.

Biasane kita terus-terusan nyedhiyakake dhukungan para pembeli sing paling teliti, uga macem-macem desain lan gaya kanthi bahan sing paling apik.Usaha kasebut kalebu kasedhiyan desain khusus kanthi kacepetan lan kiriman kanggo Mesin Blow Molding, Mesin Blowing Plastik China, Wiwit ngadegake perusahaan kita, kita wis nyadari pentinge nyedhiyakake produk kualitas apik lan layanan sadurunge-sales lan sawise-sales. .Umume masalah antarane pemasok global lan klien amarga komunikasi sing ora apik.Secara budaya, panyedhiya bisa wegah takon babagan sing ora dingerteni.Kita ngilangi alangan kasebut kanggo mesthekake yen sampeyan entuk apa sing dikarepake ing tingkat sing dikarepake, nalika sampeyan pengin.

Spesifikasi Teknis

Bengkel Pabrik

Layanan Kita

Ruang Sampel

Custormers

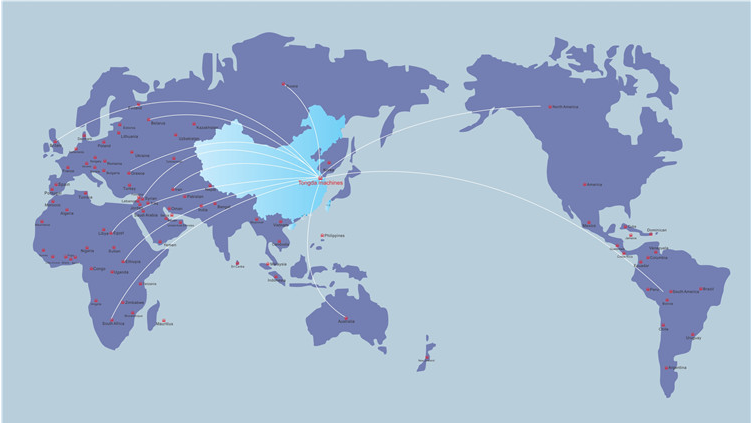

Jaringan Pemasaran Layanan

Mesin kita wis nglayani pelanggan ing saindenging jagad.

Packaging & Logistik